A group of Pennsylvania State University researchers have recently developed a unique 3D printing method to create tissue building blocks with micropores. Manufactured porous structures such as these allow both nutrients and other fluids to circulate and mark great potential for lab-generated tissues containing blood vessels.

The team claims that the micropores in artificial tissues forming cartilage and bone allow oxygen and nutrient diffusion into the tissues core.

“Cells die if nutrients and oxygen can’t get inside,” said Ibrahim T. Ozbolat, associate professor of engineering science and mechanics. “One of the problems with fabrication of tissues is that we can’t make them large in size.”

In a process by which stem cells are 3D printed from human fat combined with sodium alginate porogens extracted from seaweed, the materials can generate tiny particles that leave behind pores in tissue once dissolved.

READ MORE: Michigan Researchers use 3D Printing to Aid Arthritis Patients at Low Costs

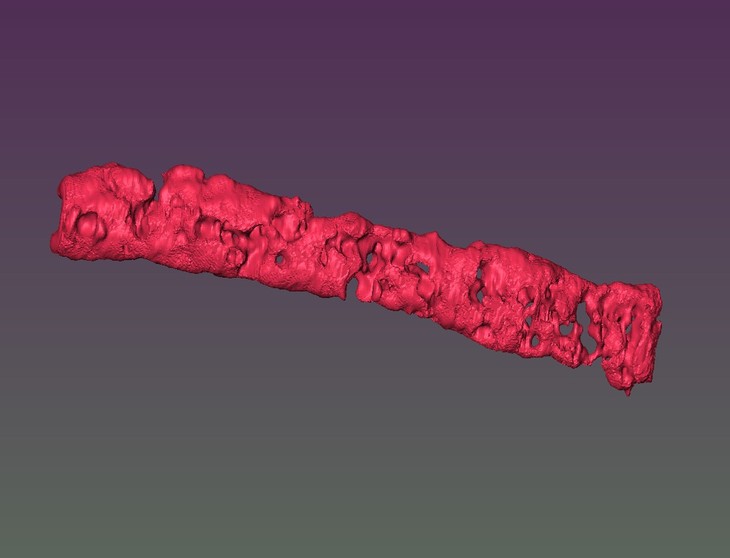

These researchers are generating tissue building blocks with unique micropores as an alternative to vascularization. If effective, this effort could help grow blood vessels within tissue. They have dubbed their product to be “porous tissue strands.”

By using the mixture of stem cells, the researchers’ 3D printed strands of undifferentiated tissue. These tissue strands are 3D printed in layers on top and adjacent to one another to form a tissue patch. When exposed to a chemical solution, this patch converts the stem cells into specific cells such as bone or cartilage. These micropores that Ozbolat created allow the fluid to flow evenly to allow of the stem cells, yielding uniform distribution.

Being that cartilage contains no blood vessels, porous structures can be created fairly easily to create implants with very natural porosity. At the moment only small patches can be made, however the researchers recently reported in Biofabrication that the synthesized strands maintained 25% porosity and pore connectivity of 85% for a minimum of three weeks.

READ MORE: CU Boulder Scientists Create 3D-Printing Technique to Make Blood Vessels

“These patches can be implanted in bone or cartilage. They can be used for osteoarthritis, patches for plastic surgery such as the cartilage in the nasal septum, knee restoration, and other bone or cartilage defects.”

Ozbolat’s research has great implications for bone and cartilage regeneration, and the researchers are considering using the technique to generate fat, muscle, and other tissue as well.

Published in paper titled “Porous tissue strands: avascular building blocks for scalable tissue fabrication,” this research was conducted by Ozbolat and colleagues Yang Wu, Monika Hospodiuk, Hemanth Gudapati, Thomas Neuberger, Srinivas Koduru, Dino J. Ravnic, and Weijie Peng.

Our recent work on inducing pores in 3D scalable tissues, an alternative to vascularization!! https://t.co/kebYjSAqAQ

— Ozbolat Lab (@OzbolatLab) December 20, 2018

Sources: 3D Printing Industry, 3D Print

© 2025 Mashup Media, LLC, a Formedics Property. All Rights Reserved.

© 2025 Mashup Media, LLC, a Formedics Property. All Rights Reserved.